10-2-1 Wiring Electric Brakes

If your vehicle is not equipped with a plug-and-play harness you can also splice in wiring for connecting a brake controller. Works with most 3500 lbs trailer axles in the market.

Amazon Com 10 X 2 25 Trailer Electric Brake 1 Right 1 Left In Pair Automotive

4 mounting bolts installed no nuts included.

10-2-1 wiring electric brakes. The RED stoplight wire must be connected to the cold side of the brake pedal stoplight switch. Connect the two wires from the clutch or pins 2 6 are connected internally. During forward travel the brakes automatically adjust to deliver optimum performance and braking power.

In most cases problems with electric trailer brakes occur either because of corrosion in the trailer connector or a break on the wiring between the connector and the brakes themselves. Tail License 3 Tail License. DEXTER Forward Self-Adjusting 10 x 2-14 Right Hand complete electric brake assemblyThe design of Nev-R-Adjust brakes utilizes an innovative forward self-adjusting feature.

I have attached an electric brake installation video for you to check out. The temperature rating on the coating is 221 degrees Fahrenheit. In Step 2 there are instructions for drilling through the firewall.

We then run a jumper wire from the electric brake power wire to the right side brake assemblies see photo. G G Electric Plumbing at 1900 NE 78th Street Ste. Brake cable is used for many automotive truck and trailer applications Flat jacketed PVC insulation Tough gray over plastic insulated wires Resistant to oil grease acids and gasoline Available with 2 3 and 4 conductors 246 x 432 625mm x 1097mm nominal OD.

Electric Brake 2 Electric Brake. Red 14 Gauge. The wire in the Jacketed 2 Wire 10 Gauge Brake Wire item 10-2-1 is stranded and designed for automotive applications.

If you want to use duplex wire you can use part 10-2-1. Home Dexter Axle Hardware Dexter Brake Assemblies Dexter Electric Brakes Dexter 10 Electric Brakes Complete 6450612 10 x 225 Electric 4400 Nev. Pair of 10 x 225 Genuine Dexter Part K23-026-00 K23-027-00 electric trailer brake assemblies with parts.

Premium LIBRA brand OE 10 x 2-14 electric trailer brake assemblies 1 left 1 right for one axle. Brake cable is constructed in two conductor configurations for 18 gauge 16 gauge 14 gauge 12 gauge and 10 gauge wire. C Make sure to tighten down fuse screws.

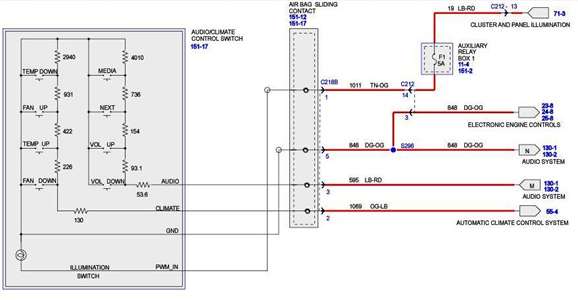

2 INSTALLATION 222 Wiring Diagrams To 24V Vehicle Brake Light trigger refer to section 221 To 12V Trailer Blue Brakes Red 25A Fuse or 30A Circuit Breaker CBK30-EB 24V Vehicle Start Battery Ground White Black-Dash mount controls for Tow-pro. Exchange with Dexter brake 023-026-00023-027-00. Common Ground 1 Common Ground.

Yellow 14 Gauge. This means that a double axle brake system would be drawing a maximum of 16 amps for a full emergency stop. The brakes are manual adjusting with access points on the backs to turn the adjuster.

Green 14 Gauge. DO NOT disturb the position of the switch. Brown 14 Gauge.

TruRyde 10 x 2-14 Electric Brake Assy. How many amps does a brake controller draw. Once the backing plate is attached to the weld rings the drum is then fitted and tightened with the axle nut.

Your factory tow package if you have one might already have this wire running from under the dash to the battery with some kind of circuit protection. - Right Hand 35k 112101. This is the wire we use to wire the brake output wire and the 12 volt power wire when.

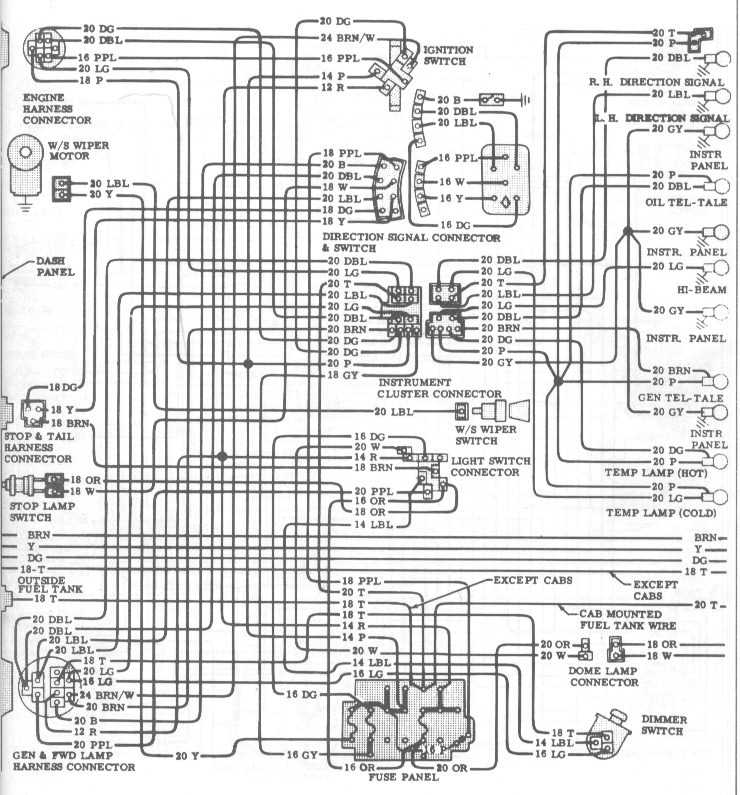

3 4 holes mounting bolt circle diameter. Connect the switch provided by the customer between terminals 7 8 and 3 as shown in the Connection diagram. 1-4 Wire the first 4 pins just like above and the 5th line goes to the brakes.

Blue 12 Gauge. 1-2 axles 30 amp for 3-4 axles to the POSITIVE terminal of the battery. This allows for use of the wire for up to 40 amps at up to 25 feet.

Black 10 Gauge. White 10 Gauge. Blue Electric Brakes or Hydraulic Reverse Disable See Blue Wire Notes below 6.

Red or Black 12V Auxiliary Power See Red Wire Notes below 7. Weve found the most common amperage draw on a 7-inch brake magnet to be 32 amps maximum. Connect the AC input to terminals 1 and 5.

The BLACK wire is the power supply line to the brake control. The F1009 by TruRyde manufacturer part numbers BK-10E-01 and BK-10E-02 is an economic choice for 10 electric brakes. The most common electrical problem is low or no voltage and amperage at the brakes.

CURT 51437 Quick Plug Electric Trailer Brake Controller Wiring Harness Select Ford F150 F250 F350 F450 F550 Super Duty Lincoln MKT Navigator black 46 out of 5 stars 118 1125 11. To relay Fuse screws To switched power source. The increased amperage of a 10 or 12-inch brake magnet tends to max out at 4 amps.

24V INPUT 125mm² 125mm² 30mm² 30mm² The Input Power Black wire should be. Black and white with gray outer jacket. This brake is rated to a maximum capacity of 3500 lbs.

B The circuit used for connection must have an 8 to 10 amp fuse. To brake booster 5 Next wire the fuse to a positive ignition switched power source. Center Auxiliary 7 Center Auxiliary.

Sizes 12 and 10 gauge are recommended for electric brake wire. Mounts to 4-hole axle brake flange. Splice down line from the switch.

101 Vancouver Washington 98665 HOW TO CALCULATE WIRE AND FUSE SIZES FOR ELECTRIC MOTORS Because electric motors have a tremendous amperage draw during the starting phase wire and fuse sizes must be calculated very carefully. 10-inch Electric brakes are suitable for any axle up to 50mm in diameter. Common causes of this condition are.

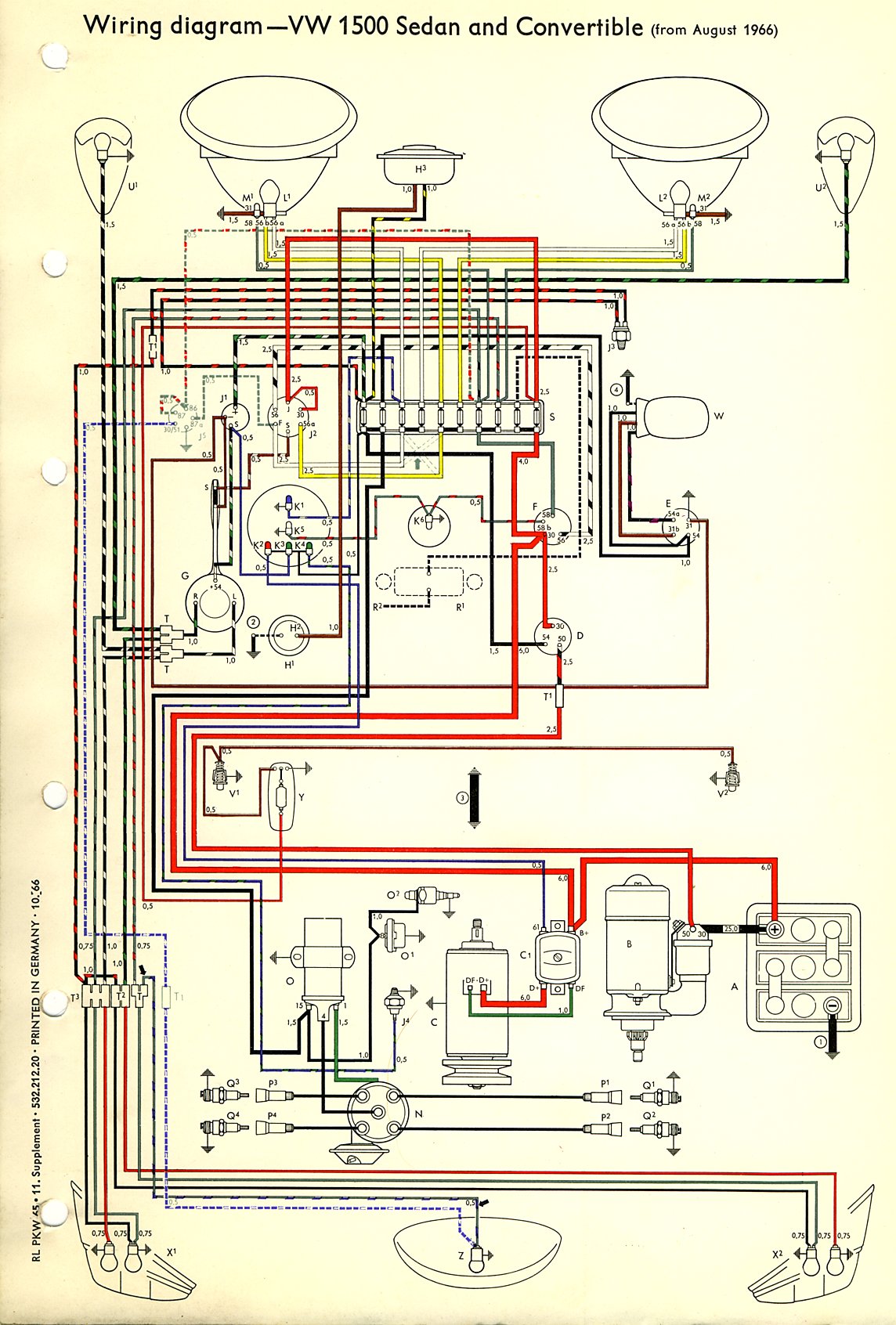

Electric trailer brake systems utilize a magnet to spread the brake shoes against the brake drum which slows the trailer down. 10 x 2-14 Right Hand complete electric brake assembly. This kit comes comes with the left hand and right hand brakes plus the hardware to mount on a 3500 lbs.

Right Stop Turn 6 Right Stop Turn. If not a wire must be run through the firewall and connected directly to the battery with an in line circuit breaker. I recommend using 12-gauge wire 12-1-1 for the jumper wire and for additional ground wire.

Battery Charge 4 Battery Charge. Connect the two wires from the brake or clutch to terminals 2 and 8 of the socket. A Positive connection must be a switched source or pump will run with key off.

The BLUE brake output wire must be connected to the trailer. Poor electrical connections open circuits insufficient wire size broken wires blown fuses fusing of brakes is not recommended improperly functioning controllers or resistors. 10-inch Electric braking systems use a four-hole weld ring to secure the 10-inch electric-backing plate to the axle.

For Alko Dexter Quality or other popular trailer axle manufacturers. Left Stop Turn 5 Stop Turn. In this guide we cover step-by-step how to install a brake controller.

Only works on 3500 lbs trailer axles with four hole brake flange. Be the first to review this product. Even during the run cycle of a motor if the voltage is low it will.

Installing a brake controller involves disconnecting the vehicle battery mounting the brake controller onto dash and plugging the unit in with a vehicle-specific wiring harness.